Gas Cutting

Also known as flame cutting or oxy-fuel cutting, this technique uses an oxygen-fuel flame to heat the metal to the ignition point before a high-velocity oxygen stream blows away the oxidized material, creating flame-cut steel profiles. Advantages include:

- Suitable for thick steel sections

- Cost-effective

- Simple process

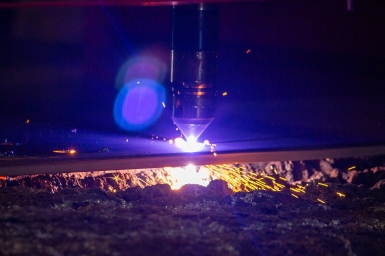

Plasma Cutting

Plasma cutting involves the use of a high-velocity jet of plasma (ionised gas). Compressed air or nitrogen is passed through an electric arc to ionise it into plasma. The plasma jet melts through the metal, while the gas flow removes the molten metal, cutting it. This type of mild steel profile cutting’s advantages includes:

- Speed

- Adaptability

- Cost-effective

Saw cutting

With saw cutting, a circular blade or band saw is used to cut steel profiles. Saw cutting’s advantages include:

- Cutting with a small tolerance

- Reduced wastage

- High-quality cuts

- Speed

- No finishing treatments

- Suitable for different metals

- Suitable for producing various shapes

Mitre cutting

Mitre cutting involves the use of a compound or sliding mitre saw fitted with a circular blade and a laser guide. This technique is used to make precise cuts at different angles. Mitre cutting’s advantages include:

Full CNC/CAD CAM programming

Computer Numerical Control (CNC) stainless steel profile cutting sees a CAD model (blueprint) converted into instructions known as G-code, which controls the machine’s movements as well as the cut depth and speed. CAM programming is a more advanced technique that uses a similar principle. Advantages include:

- Suitable for intricate shapes

- Accuracy

- Fast and efficient

- High-quality cuts

- Computer controlled